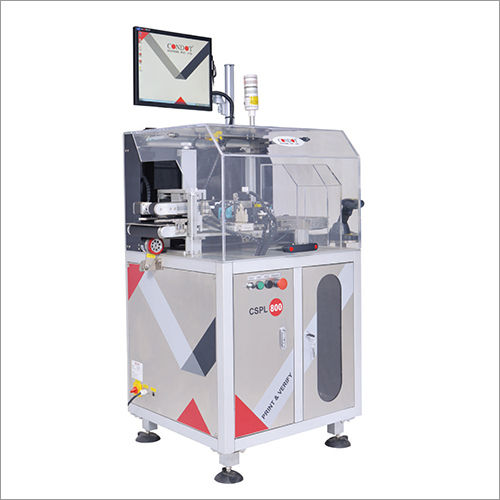

Print and Verify Track And Trace Pharma

500000 INR/Set

Product Details:

X

Print and Verify Track And Trace Pharma Price And Quantity

- 1 Set

- 500000 INR/Set

- 300000.00 - 1500000.00 INR/Set

Print and Verify Track And Trace Pharma Trade Information

- 1 Set Per Day

- 1 Week

- South India

Product Description

Technical Specification

- Compliance to : CE directives. 21 CFR part 11

- Machine dimension : Length 1735, Width 1285

- Height 2006 mm (180 + 50)

- Working height : 720 mm (180 + 50)

- Weight : 400 kg. (approx.)

- Belt Speed > 35 m/min (+5)

- Running direction : Left to right

- Cabinet : Stainless steel with key locked space for controller

- Top cover : Transparent acrylic cover equipped with safeguard switch to stop the machine if opened during production

- Rejection bin =: Acrylic rejection bin secured with key lock

- Rejection system : Air pressure box blow-out for boxes up to 250 g. Pneumatic push out devic available for >250 g products

Infeed carton separator :

- Top belt : AC synchronize motor

- Carton size : Minimum size - 20(W) X15(H) X 60(L)

- Maximum size - 300(W) X100(H) X 210(L)

Connection / Input & Output

- Electrical connection : Voltage: 230 VAC (+ 10%) Frequency : 50 / 60 Hz

- Air pressure : 5 to 7 Bar main supply

- Machine : PLC 36 Input & 24 Output

Printing System

- Technology : Print heads TU 2.5 technology

- Print height > 12.7-25.4mm/%"-1†/1 or 2 pens

- Resolution : Up to 600 dpi

- Print distance : 0.5-2.0 mm dependent onink and speed,

- Ink supply : Ink cartridges, water and solvent based inks |

- Capability : Static text, Variable text, Static barcode, Variable barcode, GS1 data matrix Barcode, Counter, Date & time, Shift code, | Static logo, Variable logo, 2 color printing, Invisible printing

Vision System

- Camera & Lenses : Camera - 1.3 megapixel and Lens - 2 megapixel with 8 mm focal length (varies on application demand)

- Inspection area : 80 (H) x 110(W) mm (Depend on selection of camera and lens)

- Light : Integrated light shielding

- Verification : Verification of printed text (OCR), Image Comparison, 1D & 2D codes, EAN13, Code128, PHARMACODE, Data Matrix, QR Code, PDF 417, AZTEC, CODE 39 & many more...

- Grading : Quality of 2D code is determined Grade level between ‘F’ and ‘A’ (0-4). With a font -based reference scheme Grade level between 0 to 100

- Qualification : In accordance with industrial standards printed items ISO/IEC 15415 and 15416

- Data matrix standard : According to GS1 and ISO/IEC 16022

- Text standard : Recommended OCR-B font

- Print position : Front/Rear side

- Throughput : Up to 250 cartons per minute

- Display : 17†Touch monitor

- Software : CSPL 1900 GUI to control all parameters and to comply with 21 CFR Part 11

Label Applicator

- Label material : Paper/Film

- Release paper : Glassine Paper/Film

- Label gap : 3mm

- Label roll Dia. : Max.-OD 280 mm and ID 76mm

- Label height >: Max. - 100 mm

- Label height : Labeler suitable for label roll from 25 mm setting to 100 mm in height

- Labeling head : 150 mm adjustment each on both axis. adjustment horizontal and vertical

- Speed : 250 Labels/min

- Labeling head : 2 No's

- Bollinig labeling : Optional, machine dimension will change Head

Enter Buying Requirement Details

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese